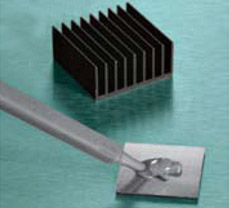

The key feature of THERMFLOW materials is their phase-change characteristic. At room temperature, THERMFLOW materials are solid and easy to handle. This allows them to be consistently and cleanly applied as dry pads to a heat sink or component surface. THERMFLOW material softens as it reaches component operating temperatures. With light clamping pressure it will readily conform to both mating surfaces, similar to thermal grease. This ability to completely fill interfacial air gaps and voids typical of component packages and heat sinks allows THERMFLOW pads to outperform nonflowing elastomeric or graphite-based thermal pads and achieve performance comparable to thermal grease.

THERMFLOW materials are electrically non-conductive. However, since metal-to-metal contact is possible after the material undergoes phase-change in a typical heat sink assembly, THERMFLOW pads should not be used as electrical insulators.

Test Method Color |

N/A Visual |

Color |

N/A Gray |

Carrier |

N/A None - Free film |

Test Method Thicknesses |

N/A ASTM D374 |

Standard Thickness |

N/A 0.125 mm0.005 in |

Test Method Specific Gravity |

N/A ASTM D792 |

Specific Gravity |

N/A 2.4 |

Test Method Phase Transition Temperature |

N/A ASTM 3418 |

Phase Transition Temperature |

N/A 45/62 ºC |

Weight Loss, 125 ºC for 48 h |

N/A < 0.5 % |

Test Method Thermal Impendance |

N/A ASTM D5470 |

Thermal Impendance at 70 ºC, at 69 kPa (10 psi) |

N/A 0.13 ºC-cm²/W0.02 ºC-in²/W |

Thermal Impendance at 70 ºC, at 172 kPa (25 psi) |

N/A 0.097 ºC-cm²/W0.015 ºC-in²/W |

Thermal Impendance at 70 ºC, at 345 kPa (50 psi) |

N/A 0.052 ºC-cm²/W0.008 ºC-in²/W |

Operating Temperature Range |

N/A –55 to 125 ºC–67 to 257 ºF |

Test Method Volume Resistivity |

N/A ASTM D257 |

Volume Resistivity |

N/A Nonconductive |

Test Method Voltage Breakdown |

N/A ASTM D149 |

Test Method Flammability Rating |

N/A UL 94 |

Flammability Rating |

N/A Not tested |

Test Method RoHS Compliant |

N/A Chomeric Certification |

RoHS Compliant |

N/A Yes |

Test Method Shelf Life |

N/A Chomerics |

Shelf Life, Months from Date of Shipment |

N/A 12 |

Robert McKeown offers a variety of adhesive and sealant products for a wide range of commercial and industrial applications. Our silicone epoxy adhesives and sealants, in particular, are ideal for applications such as:

FEATURES AND USES OF ELECTRONICS SEALANTS AND ADHESIVES

Providing ultimate reliability and longevity, our electronics adhesives and sealants can be used to form bonds to many different surfaces and substrates, including:

- Ceramics

- Metals

- Glass

- Filled plastics

These specialized solutions eliminate the need for mechanical fastening and clamping while allowing for optimal ease of processing. Reliable and efficient in temperatures ranging from -45 °C to 200 °C, our electronics adhesives and sealants provide excellent dielectric insulation.

Most silicone formulations are solventless, eliminating the need for special storage, ventilation, or handling. And because many of our electronics adhesives and solvents are reworkable, they offer great flexibility and allow for easier module repair.

Electronics adhesives and sealants are frequently used in: automotive, communications, industrial, and energy industries, as well as consumer devices.

Extremely versatile, these adhesives can be used for:

- Sealing lids and housing grooves

- Cushioning or stabilizing fragile components

- Affixing components such as capacitors and coils to circuit boards

- Adhering module lids and baseplates

- Gasketing

SILICONE ADHESIVES

One of the most popular types of electronics adhesives, silicone adhesives provide excellent flexibility and high heat resistance, making them ideal for electrical, automotive, aerospace, and construction industries. There are several varieties of silicone adhesives available, including:

- Two-component systems that require a curing agent

- One-component systems that cure through air moisture

- UV or EB radiation curing adhesives

- Pressure-sensitive versions that adhere to surfaces with little pressure

RTV sealants (room-temperature vulcanizing) begin to cure as soon as they’re exposed to moisture in the air, so they must be used quickly. Pressure-sensitive sealants offer a permanent tackiness. UV- or radiation-cured sealants, on the other hand, require UV light to cure, while thermoset silicone sealants require heat to cure. Although not as strong as other sealants or adhesives, electrical silicone sealants remain flexible even when fully dried or cured. Various types of silicone sealants serve as ideal solutions for high-heat applications like engine gaskets.

In electronics fabrication, silicone adhesive sealants are often used for fixing parts on circuit boards, LCD module assembly, general sealing, and component protection. Specific formulations differ depending on intended use and can be customized to allow for enhanced thermal conductivity, superior protection of metal electrodes, and faster cure times. These sealants are available in chemical-, heat-, mildew-, and oil-resistant formulations to meet a wide range of application needs.

Industrial silicone epoxy is used for:

- General-purpose fixture sealing of tubs

- Windows, ductwork

- Gaskets

- General-purpose bonding

- Sealing

THERMAL SEALANTS

High temperatures often present problems for conventional adhesive materials and can affect printed circuit boards and assemblies. At Robert McKeown, we offer the highest-level special adhesive grades of thermal sealants, which allow for enhanced thermal conductivity. Both low-viscosity liquids and non-slump formations are available in two-cure chemistries.

We also offer one-part moisture-cure grades, which use room-temperature processing to cut back on equipment needs. After cure, the materials form strong but flexible bonds, which protect from mechanical stress and vibration. Both one- and two-part heat-cure solutions accelerate processing and support high throughput production.

Heat resistant silicone adhesives are extremely versatile materials and dispense easily at room temperature, but can also cure quickly at any thickness level at temperatures as low as 90°C. Efficacy and functionality are improved when higher temperatures accelerate cure times.

CHEMICAL RESISTANT ADHESIVES

Chemical resistant silicone adhesives are commonly used in:

- Chemical processing plants

- Chemical piping and tanks

- Medical devices

These adhesives can reliably protect against a wide range of chemicals and harsh materials, including acid, alcohol, and fuel. Depending on specific application requirements, they can also provide resistance against solvents, bases, sterilization, and water.

EPOXY BASED ADHESIVES

Epoxy based adhesives are created by mixing a resin and a hardener. Curing is initiated when the resin is mixed with a certain catalyst. The covalent bonds resulting from this combination determine the rigidity and strength of the epoxy sealant.

Epoxy adhesives can reliably adhere to a variety of materials and are ideal for applications demanding chemical resistance, high strength, and low stress. Thermally conductive, microelectronic-grade, general-purpose, high-temperature and chemical resistant epoxy adhesives are available as both one- and two-part solutions. Epoxy adhesive and sealants allow for room temperature, thermal, or UV-curing capabilities.