Electrical Insulation and Isolation Tapes

To provide reliable protection, electronic safety isolation methods must be used to physically separate hazardous circuits from users and surrounding equipment. Available in many different varieties, electrically insulating materials wrap, seal, and insulate cables, circuit boards, and other electric components. Electrical insulation tapes, in particular, provide the reliability and versatility needed in these critical applications, limiting overvoltage and isolating circuits that could be hazardous if connected.

Improper isolation techniques greatly increase the risk of injuries and deaths within a workplace or built environment; for instance, without isolation, increased voltage of measuring instruments can cause electric shocks, burns, and fire hazards. Overvoltage issues can also be caused by lightning strikes or strong power surges in heavy-duty equipment, and even short-lived voltage spikes can cause data errors, equipment damage, and reduced performance.

Types of Electrical Insulation Tape

Making use of insulating tapes for isolation eliminates the risk of direct electrical connection between two or more circuits or their adjacent parts. The tape is rolled around the wires to provide insulation and prevent the flow of harmful currents from AC or DC differences between circuits.

The specific properties and benefits of insulating tapes vary depending on their construction material. Below are some of the most popular types of electrical isolation tape.

Black Vinyl Tape

This is the industry standard thanks to its ability to withstand a wide range of elements. Although durable and strong, it can also be easily removed with minimal residue. Black vinyl tape has excellent UV resistance.

Transformer Insulation Tape

This tape can withstand high heat and flames and has outstanding adhesive properties, making it well-suited for lead insulation, as well as coil wrapping and banding. And because transformer electrical insulation tape can produce a tight coil construction, it can be used within the layers of both dry-type and oil-filled transformers.

Dielectric Tape or Electrical Insulation Tape

Used for wrapping, marking, and splicing electrical connections such as cables and wires, these tapes typically have voltage ratings. Helping to prevent shorting between various types of ground wire, they offer superior adhesive holding power to a variety of materials and can also offer resistance to cleaning solvents and oil.

Polyimide Film Tape

A thin film tape with superior heat resistance, polyimide film tape can also be used in lower temperatures. Its thin construction is particularly useful for wave solder masking, as well as the production of flexible circuit materials. It also reduces adhesive transfer, reducing the need for cleaning, and has great dielectric strength and abrasion resistance. Service temperatures range from -100°F to +500°F (-73°C to +260°C). This tape can be used in a wide range of environments thanks to its excellent electrical, mechanical, and chemical properties.

Thermal Insulating Tape

Used to keep high heat away from wires, cables, hoses, and other equipment, this electrical isolation tape becomes sticky when heated, allowing for adhesive flexibility; cooling allows for easy repositioning or removal of parts during assembly. These tapes are used near equipment that poses fire hazards, such as engines and furnaces.

Learn More

A family-owned fabricating distributor of engineered materials since 1937, Robert McKeown Co., Inc. is proud to offer a wide range of electrical insulation and isolation tapes. To learn more about the various types of electrical isolation tapes available or discuss how they can help protect your facility and workers — and your bottom line — reach out the team today.

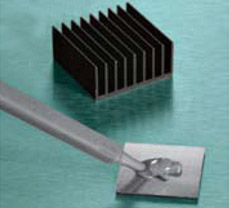

/Asset/a1167.jpg

Heat Sealing Tapes

Saint-Gobain Performance Plastics CHR® brand pressure sensitive adhesive tapes, constructed of fiberglass fabric impregnated with pure polytetrafluorethylene (PTFE) and coated with adhesive provide superior non-stick surfaces, allow your equipment to work smoothly and more efficiently.The CHR series has been designed to meet the tough requirements demanded by the packaging industry: high speed durability, long life at high temperature.

CHR tapes are widely used on L-bar sealers, jaws, drawers, irons and form-fill-seal machinery. These products can be used to seal cellophane, polyethylene, polypropylene, wax paper, foils, and other laminated packaging materials.

CHR tapes offers superior constructed substrates of pure PTFE and fiberglass coated with premium adhesives formulated for operating at high temperature. Also, lower temperature acrylic adhesive is available for those applications where just non-stick or anti-friction is required. /Asset/pic58.jpg

Robert McKeown offers a variety of adhesive and sealant products for a wide range of commercial and industrial applications. Our silicone epoxy adhesives and sealants, in particular, are ideal for applications such as:

FEATURES AND USES OF ELECTRONICS SEALANTS AND ADHESIVES

Providing ultimate reliability and longevity, our electronics adhesives and sealants can be used to form bonds to many different surfaces and substrates, including:

- Ceramics

- Metals

- Glass

- Filled plastics

These specialized solutions eliminate the need for mechanical fastening and clamping while allowing for optimal ease of processing. Reliable and efficient in temperatures ranging from -45 °C to 200 °C, our electronics adhesives and sealants provide excellent dielectric insulation.

Most silicone formulations are solventless, eliminating the need for special storage, ventilation, or handling. And because many of our electronics adhesives and solvents are reworkable, they offer great flexibility and allow for easier module repair.

Electronics adhesives and sealants are frequently used in: automotive, communications, industrial, and energy industries, as well as consumer devices.

Extremely versatile, these adhesives can be used for:

- Sealing lids and housing grooves

- Cushioning or stabilizing fragile components

- Affixing components such as capacitors and coils to circuit boards

- Adhering module lids and baseplates

- Gasketing

SILICONE ADHESIVES

One of the most popular types of electronics adhesives, silicone adhesives provide excellent flexibility and high heat resistance, making them ideal for electrical, automotive, aerospace, and construction industries. There are several varieties of silicone adhesives available, including:

- Two-component systems that require a curing agent

- One-component systems that cure through air moisture

- UV or EB radiation curing adhesives

- Pressure-sensitive versions that adhere to surfaces with little pressure

RTV sealants (room-temperature vulcanizing) begin to cure as soon as they’re exposed to moisture in the air, so they must be used quickly. Pressure-sensitive sealants offer a permanent tackiness. UV- or radiation-cured sealants, on the other hand, require UV light to cure, while thermoset silicone sealants require heat to cure. Although not as strong as other sealants or adhesives, electrical silicone sealants remain flexible even when fully dried or cured. Various types of silicone sealants serve as ideal solutions for high-heat applications like engine gaskets.

In electronics fabrication, silicone adhesive sealants are often used for fixing parts on circuit boards, LCD module assembly, general sealing, and component protection. Specific formulations differ depending on intended use and can be customized to allow for enhanced thermal conductivity, superior protection of metal electrodes, and faster cure times. These sealants are available in chemical-, heat-, mildew-, and oil-resistant formulations to meet a wide range of application needs.

Industrial silicone epoxy is used for:

- General-purpose fixture sealing of tubs

- Windows, ductwork

- Gaskets

- General-purpose bonding

- Sealing

THERMAL SEALANTS

High temperatures often present problems for conventional adhesive materials and can affect printed circuit boards and assemblies. At Robert McKeown, we offer the highest-level special adhesive grades of thermal sealants, which allow for enhanced thermal conductivity. Both low-viscosity liquids and non-slump formations are available in two-cure chemistries.

We also offer one-part moisture-cure grades, which use room-temperature processing to cut back on equipment needs. After cure, the materials form strong but flexible bonds, which protect from mechanical stress and vibration. Both one- and two-part heat-cure solutions accelerate processing and support high throughput production.

Heat resistant silicone adhesives are extremely versatile materials and dispense easily at room temperature, but can also cure quickly at any thickness level at temperatures as low as 90°C. Efficacy and functionality are improved when higher temperatures accelerate cure times.

CHEMICAL RESISTANT ADHESIVES

Chemical resistant silicone adhesives are commonly used in:

- Chemical processing plants

- Chemical piping and tanks

- Medical devices

These adhesives can reliably protect against a wide range of chemicals and harsh materials, including acid, alcohol, and fuel. Depending on specific application requirements, they can also provide resistance against solvents, bases, sterilization, and water.

EPOXY BASED ADHESIVES

Epoxy based adhesives are created by mixing a resin and a hardener. Curing is initiated when the resin is mixed with a certain catalyst. The covalent bonds resulting from this combination determine the rigidity and strength of the epoxy sealant.

Epoxy adhesives can reliably adhere to a variety of materials and are ideal for applications demanding chemical resistance, high strength, and low stress. Thermally conductive, microelectronic-grade, general-purpose, high-temperature and chemical resistant epoxy adhesives are available as both one- and two-part solutions. Epoxy adhesive and sealants allow for room temperature, thermal, or UV-curing capabilities.