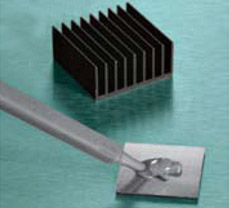

Each SOFT-SHIELD 5000 Series gasket consists of an electrically conductive fabric jacket over a highly compressible urethane foam core. The nickel-plated, woven nylon rip-stop jacket is selfterminating when cut. Chosen for its excellent compressibility, the foam core typically requires less than 1 lb/in (0.175 N/mm) closure force, making it especially useful for thin-walled plastic enclosures. Standard pressure-sensitive adhesive attachment tape (PSA) makes SOFT-SHIELD 5000 Series gaskets a user-friendly and cost-effective design solution.

Every profile in the SOFT-SHIELD 5000 Series can be provided in a General Duty version or a UL 94V-0 rated version, as needed, with no difference in performance.

Features

- Choice of General Duty or UL 94V-0 rated versions

- Typically require < 1 lb/in (0.175 N/mm) closure force – 5 times lower than other gaskets

- > 90 dB attenuation from 20 MHz to 10 GHz

- Asymmetrical profiles, as well as “C”, “V”, “P”, “D” shapes

- No performance degradation after 10,000 compression cycles

- Wide release liner for easy removal

- Kiss-cut parts on release sheets for easy “peel-and-stick”

- grounding applications

- Self-terminating jacket – no sharp edges

- Tested to Bellcore GR-64-Core Airborne Contaminants requirements

- Custom lengths, custom profiles

- Cost-effective

- Alternative to BeCu fingerstock

- Pick and place installation

- Technical application support

- Global distributor/fabricator network

- Application-ready custom parts (die-cut, spliced, etc.)

| Items |

/Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg /Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg 82-111-74018 SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips |

/Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg /Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg 82-111-74017 SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips |

/Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg /Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg 82-111-74022 SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips |

/Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg /Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg 82-111-74024 SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips |

/Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg /Asset/SOFT-SHIELD-5000-Low-Closure-Force-EMI-Strip-Gaskets---Square-Strips.jpg 82-111-74028 SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips |

|||||

| Jacket Type | N/A Nickel-plated nylon rip-stop fabric | |||||||||

| PSA Tape Backing | N/A No PSA tape | |||||||||

| Gasket Service Rating | N/A General duty (urethane foam core) | |||||||||

| Profile Number | N/A 74018 | N/A 74017 | N/A 74022 | N/A 74024 | N/A 74028 | |||||

| Height | N/A 0.118 in3.00 mm | N/A 0.200 in5.08 mm | N/A 0.236 in6.00 mm | N/A 0.375 in9.53 mm | N/A 0.500 in12.70 mm | |||||

| Width | N/A 0.118 in3.00 mm | N/A 0.200 in5.08 mm | N/A 0.236 in6.00 mm | N/A 0.375 in9.53 mm | N/A 0.500 in12.70 mm | |||||

| Conductive Pressure-Sensitive Adhesive | N/A Non-conductive adhesive | |||||||||

| Operating Temperature Range | N/A –40 to 70 ºC | |||||||||

| Test Method Compression Set | N/A ASTM D3574 (modified) | |||||||||

| Compression Set | N/A < 15 % | |||||||||

| Test Method Electrical Conductivity | N/A CEPS-0002 | |||||||||

| Electrical Conductivity Max. | N/A 0.1 O/sq | |||||||||

| Test Method Adhesive Peel Strength | N/A ASTM D1000 (90° Bend) | |||||||||

| Adhesive Peel Strength Min. | N/A 4 lb/in0.7 N/mm | |||||||||

| Product Forms | N/A SQ, REC., D, C, P, L and Custom | |||||||||

| Typical Applications | N/A Doors, Panels, Seams, Faceplates, Ground Pads | |||||||||

| Method of Manufacture | N/A Dispensed foam | |||||||||

| Jacket Material | N/A Ni/Ag Plated rip-stop Nylon | |||||||||

| Foam | N/A High Performance Urethane Foam | |||||||||

| Attachment Method (PSA) | N/A Non conductive, high temp, high tack, closed cell, acrylic PSA | |||||||||

| Baseline EMI Shielding | N/A 90 dB | |||||||||

| Shielding Effectiveness After Cycling | N/A Better | |||||||||

| Softness | N/A Better | |||||||||

| Compression Set ASTM D395 - Method B | N/A 70 ºC - 10 % | |||||||||

| RoHS Compliant | N/A Yes | |||||||||

| Configurations |

N/A

Gaskets are supplied in standard 8-foot lengths or cut-to-length strips. Depending on the profile, gasketing can also be supplied on spools. For rapid peel-and-stick grounding applications, the material is supplied as kiss-cut parts on polyester film release backers, or as individual pieces. Chomerics also fabricates single-piece, spliced picture frame gaskets from continuous lengths. With their fully jacketed surfaces, these gaskets are ideally suited for low closure force applications that require 360° EMI shielding, or the ease of installing a onepiece gasket. Chomerics’ Applications Engineering department welcomes the opportunity to provide assistance with design and prototype fabrication of SOFT-SHIELD 5000 Series EMI Gaskets in custom profiles. |

|||||||||

| Typical Application-Ready Solutions |

N/A

Mobile phone grounding Conditions and Requirements SOFT-SHIELD Gasket Solution Interface between aluminum casting and plastic antenna housing Conditions and Requirements SOFT-SHIELD Gasket Solution |

|||||||||

| Typical Tolerances |

N/A

Typical cross section tolerances: ±0.010 in. (0.25 mm) for all dimensions up to 0.04 in. (1.02 mm) ±0.020 in. (0.51 mm) for all dimensions above 0.04 in. (1.02 mm) Detailed part drawings are available on request. Typical length tolerances: 0.10 to 6.0 in. (0.25 to 15.2 cm) ± 0.030 in. (0.76 mm) 6.1 to 18.0 in. (15.5 to 45.7 cm) ± 0.060 in. (1.52 mm) 18.1 to 42.0 in. (46.0 to 106.7 cm) ± 0.075 in. (1.91 mm) 42.1 to 96.0 in. (107.0 to 243.8 cm) ± 0.090 in. (2.29 mm) Typical kiss-cut tolerances: 0.04 to 0.12 in. (1.02 to 3.05 mm) ± 0.015 in. (0.38 mm) 0.121 to 0.40 in. (3.07 to 10.16 mm) ± 0.035 in. (0.89 mm) |

|||||||||

|

|

||||||||||

Robert McKeown offers a variety of adhesive and sealant products for a wide range of commercial and industrial applications. Our silicone epoxy adhesives and sealants, in particular, are ideal for applications such as:

FEATURES AND USES OF ELECTRONICS SEALANTS AND ADHESIVES

Providing ultimate reliability and longevity, our electronics adhesives and sealants can be used to form bonds to many different surfaces and substrates, including:

- Ceramics

- Metals

- Glass

- Filled plastics

These specialized solutions eliminate the need for mechanical fastening and clamping while allowing for optimal ease of processing. Reliable and efficient in temperatures ranging from -45 °C to 200 °C, our electronics adhesives and sealants provide excellent dielectric insulation.

Most silicone formulations are solventless, eliminating the need for special storage, ventilation, or handling. And because many of our electronics adhesives and solvents are reworkable, they offer great flexibility and allow for easier module repair.

Electronics adhesives and sealants are frequently used in: automotive, communications, industrial, and energy industries, as well as consumer devices.

Extremely versatile, these adhesives can be used for:

- Sealing lids and housing grooves

- Cushioning or stabilizing fragile components

- Affixing components such as capacitors and coils to circuit boards

- Adhering module lids and baseplates

- Gasketing

SILICONE ADHESIVES

One of the most popular types of electronics adhesives, silicone adhesives provide excellent flexibility and high heat resistance, making them ideal for electrical, automotive, aerospace, and construction industries. There are several varieties of silicone adhesives available, including:

- Two-component systems that require a curing agent

- One-component systems that cure through air moisture

- UV or EB radiation curing adhesives

- Pressure-sensitive versions that adhere to surfaces with little pressure

RTV sealants (room-temperature vulcanizing) begin to cure as soon as they’re exposed to moisture in the air, so they must be used quickly. Pressure-sensitive sealants offer a permanent tackiness. UV- or radiation-cured sealants, on the other hand, require UV light to cure, while thermoset silicone sealants require heat to cure. Although not as strong as other sealants or adhesives, electrical silicone sealants remain flexible even when fully dried or cured. Various types of silicone sealants serve as ideal solutions for high-heat applications like engine gaskets.

In electronics fabrication, silicone adhesive sealants are often used for fixing parts on circuit boards, LCD module assembly, general sealing, and component protection. Specific formulations differ depending on intended use and can be customized to allow for enhanced thermal conductivity, superior protection of metal electrodes, and faster cure times. These sealants are available in chemical-, heat-, mildew-, and oil-resistant formulations to meet a wide range of application needs.

Industrial silicone epoxy is used for:

- General-purpose fixture sealing of tubs

- Windows, ductwork

- Gaskets

- General-purpose bonding

- Sealing

THERMAL SEALANTS

High temperatures often present problems for conventional adhesive materials and can affect printed circuit boards and assemblies. At Robert McKeown, we offer the highest-level special adhesive grades of thermal sealants, which allow for enhanced thermal conductivity. Both low-viscosity liquids and non-slump formations are available in two-cure chemistries.

We also offer one-part moisture-cure grades, which use room-temperature processing to cut back on equipment needs. After cure, the materials form strong but flexible bonds, which protect from mechanical stress and vibration. Both one- and two-part heat-cure solutions accelerate processing and support high throughput production.

Heat resistant silicone adhesives are extremely versatile materials and dispense easily at room temperature, but can also cure quickly at any thickness level at temperatures as low as 90°C. Efficacy and functionality are improved when higher temperatures accelerate cure times.

CHEMICAL RESISTANT ADHESIVES

Chemical resistant silicone adhesives are commonly used in:

- Chemical processing plants

- Chemical piping and tanks

- Medical devices

These adhesives can reliably protect against a wide range of chemicals and harsh materials, including acid, alcohol, and fuel. Depending on specific application requirements, they can also provide resistance against solvents, bases, sterilization, and water.

EPOXY BASED ADHESIVES

Epoxy based adhesives are created by mixing a resin and a hardener. Curing is initiated when the resin is mixed with a certain catalyst. The covalent bonds resulting from this combination determine the rigidity and strength of the epoxy sealant.

Epoxy adhesives can reliably adhere to a variety of materials and are ideal for applications demanding chemical resistance, high strength, and low stress. Thermally conductive, microelectronic-grade, general-purpose, high-temperature and chemical resistant epoxy adhesives are available as both one- and two-part solutions. Epoxy adhesive and sealants allow for room temperature, thermal, or UV-curing capabilities.