-

Electrical Insulation and Isolation Tapes

electrical-insulation-and-isolation-tapes

-

High Temperature Film

PTFE films provide a conformable release surface and exhibit a remarkably low coefficient of friction and non-stick properties. PTFE films have high temperature resistance and are virtually unaffected by all chemicals. At elevated temperatures, PTFE film still retains excellent tensile strength. Service temperatures range from -100°F to +500°F (-73°F to +260°C). Film applications include high temperature coil and capacitor wrapping, composite bonding, masking, and conveyor release linings.

-

Polyester Films

Polyester films have excellent dimensional stability, high tensile, tear, and impact strengths, and ultimate elongation up to 120% of its original dimensions. These films exhibit low water absorption and good resistance to oils, greases, strong acids, and organic solvents. They also retain electrical properties, dielectric strength and dielectric constant in continuous operating temperatures from -100 °F to 350 °F (-73 °C to 177 °C).

Applications include transformer and capacitor wrapping, printed circuit board fabrication, splicing tapes, composite bonding protection, and low-cost masking. -

Polyester Films

Polyester Films

(11)Polyester Tapes exhibit excellent conformability and high dielectric strength per mil of thickness. Acrylic adhesives enhance these films by giving the products good chemical and solvent resistance.

-

Film Products

Film Products

(50)Nitto Denko’s adhesive tapes with film backing have a broad range of applications, mainly in various types of electronic components. Applications include electrical insulation as well as the winding and holding of elements in secondary batteries.

-

Glass Cloth

CHR® 2905 is manufactured from heat-resistant fiberglass cloth backing coated with high-temperature silicone adhesive on both sides. 2905 has a wide variety of uses in the industrial and electrical markets. It is most widely used as a high-temperature masking tape for metalizing or plasma spray coatings. 2905 is also used as a holding tape for components on circuit boards, inner wraps for coils and transformers, and high-temperature splicing.

CHR® 2915 and 2916 are manufactured from heat-resistant fiberglass cloth backing coated with high-temperature silicone adhesive. 2915 and 2916 are very versatile tapes used for general industry electrical maintenance to high-temperature splicing and wrapping. Some specific applications are over-wrap on motor rewinds, protective wrapping for wire and cables and high-temperature masking tape for welding stainless steel. These tapes also perform as a light duty plasma or flame spray masking tape.

CHR® G551, G561, G565, G569 tapes are manufactured from electrical grade fiberglass cloth backing coated with clear pressure-sensitive adhesive. The G Series tapes are constructed to offer excellent solvent and flagging resistance. The high conformance and strength/weight ratio makes this series a good candidate for oil and motor applications. -

Glass Cloth Tape

Glass Cloth Tape

(7)Flexibility and conformability are key features of this product group. High heat resistance and tensile strength of the glass cloth fulfill many electrical insulation application requirements.

-

Acetate Cloth

3M™ Acetate Cloth Tape is an aesthetically pleasing tape which offers excellent conformability in coil wrapping applications up to 105 °C.

3M™ Acetate Cloth Tape also offers excellent absorption of resins and varnishes. Available in custom widths from 1/8 in to 24 in, and comes standard on a 72 yd roll on a 3 inch diameter core. -

Cloth Products

Cloth Products

(18)Nitto Denko’s cloth adhesive tapes have a diversity of applications that include insulating electrical and electronic equipment and protective insulation of wire harnesses. We offer a wide variety of tapes with cloth backing to meet temperature, workability and other requirements.

-

Glass Filament Tape

The glass filament, coupled with polyester film, provides a high tensile strength, making these products excellent choices for heavy duty bundling and insulation.

-

Polyimide Film

Polyimide films are employed because of their extreme heat resistance. Service temperatures range from -100 °F to +500 °F (-73 C to +260 °C). These flame retardant films exhibit high tensile strength and conformability, good solvent resistance, excellent dielectric strength and good abrasion resistance.

Polyimide tape applications include electrical insulation, capacitor, transformer, and coil wrapping, electronic assembly, and wave solder protection. -

Polyimide Films

Polyimide Films

(4)The heat resistance and dielectric strength of polyimide tapes make them excellent choices for high temperature insulation and processing applications.

-

Acetate Cloth Tape

Acetate cloth backing and a thermosetting rubber adhesive system create a hand tearable product with high adhesion, conformability, printability and excellent insulating properties.

-

Composite Bonding PTFE Products

These adhesive tapes with a PTFE film backing feature excellent electrical properties, heat resistance, chemical resistance, low coefficient of friction and non-tackiness, and include tape coated with a silicon adhesive that has superior heat-resistant properties and tape with a polyester liner that raises workability for punching and application.

-

Speciality Tape

Speciality Tape

(4)The unique characteristics of these tapes make them ideally suited for high voltage insulation applications. Zone coating allows for complete impregnation of the varnish.

-

Polyester Laminates

3M™ Composite Film Tape construction combines the high dielectric strength and edge-tear resistance of polyester film with the good cushioning properties of non-woven polyester mat. It is available in five thicknesses.

Available in custom widths from 1/8 in to 24 in, and comes standard on a 3 inch diameter core. -

Polyester Laminate Tape

The two constructions of these laminates each offer unique properties. Paper/Polyester offers bulk, stiffness and is hand tearable. Polyester/Non-Woven offers excellent puncture resistance, conformability and with acrylic adhesives, higher temperature performance.

-

Foil Products

Aluminum and copper foil tapes offer high conformability, conductivity, and reflectivity at elevated temperatures. Aluminum is available with a fiberglass laminate for applications requiring higher tear strengths. Service temperatures range from -100 °F to +500 °F (-73 °C to +260 °C). Applications include thermal spray, aircraft repainting, EMI/RFI shielding, and electroplating.

-

Foil Products

Foil Products

(4)Nitto Denko’s foil products are engineered to provide the highest EMI/RFI shielding effectiveness available in a pressure sensitive tape. Our interlined products permit ease of die cutting and are highly conformable for convenient application.

-

PTFE Products

3M™ Film Tapes PTFE are high-temperature tapes used in applications requiring consistent performance and minimum shrinkage across a wide range of temperatures.

3M™ Film Tapes PTFE are extremely resistant to chemicals, have high arc resistance and are free of carbonizing materials. Available in custom widths from 1/8 inch to 24 inch, and comes standard on a 36 yard roll on a 3 inch diameter core. -

Paper Electronics

Paper tapes are designed to provide high temperature and excellent solvent resistance for wave soldering, printed circuit board masking, and hot air leveling applications. Service temperatures range from -100 °F to +500 °F (-73 °C to +260 °C).

-

Paper Electronic Tape

Paper Electronic Tapes are designed to satisfy a variety of in-process and packaging needs of "Through-Hole" electronic component manufacturers.

-

Combination Products

Combination Products

(19)Achieving high-insulation properties, these adhesive tapes feature polyester non-woven fabric and epoxy resin-impregnated polyester non-woven fabric applied to a polyester film.

-

Strip-N-Stick Silicone Tape

Strip-N-Stick® tape provides all the benefits of silcone rubber in an easy-to-apply, pressure-sensitive adhesive tape form. Compressible and flexible, it can conform to irregular surfaces, wrap over cylinders or be formed to produce right angles. Applications include gasketing, vibration damping, and thermal insulation.The tape reduces the need for expensive diecut- parts – you don‘t pay for the center. It also eliminates the high cost of bonding and will be slit to order from 1/2" and up.

100S is a silicone sponge with high temperature silicone adhesive.

200A is a silicone sponge with aggressive acrylic adhesive.

300AR is reinforced silicone sponge with aggressive acrylic adhesive. Its unique construction provides compressibility of sponge and dimensional stability of fiberglass reinforcement. Stretch is eliminated, which contributes to the consistent size and shape of cut parts and inhibits outward extrusion under high pressure. It further permits close tolerance slitting.

440S is a 1/32" thick Shore A 30 durometer silicone solid with high-temperature silicone adhesive.

440A combines 30 durometer solid rubber with a high-adhesion acrylic adhesive for an excellent 1/32" thick gasket material. It provides high elongation and good comformability.

512AF uses SGPPL CHR’s silicone foam along with film-supported acrylic pressure-sensitive adhesive.

Adhesive temperature range for Silicone PSA is –100 °F to +500 °F and for Acrylic PSA, –20 °F to +300 °F. -

Silicone Sponge Rubber Tape

Flexible, compressible COHRlastic silicone closed cell sponge is designed for high-performance gasketing, thermal shielding, vibration mounts and press pads. It is available in six constructions.

R10470, a general-purpose silicone sponge, can be used in most applications.

R10480 has extremely low compression set and maintains its resiliency even under extended compression.

R10460 is flame retardant.When held in a vertical position and exposed to a 2,000 °F flame for 12 seconds, there is no residential flame and less than a 10 second afterglow. Like R10480, it is especially resistant to compression set.

R10450 silicone sponge with fiberglass reinforcement is a unique construction. It has the compressibility of sponge, plus dimensional stability in the X-Y direction. The absence of stretch contributes to the consistent size and shape of die cut parts and eliminates outward extrusion under pressure.

R10490 fluorosilicone sponge rubber can be used as a gasket where it is necessary to contain fluids that would degrade normal silicone sponge and solid materials (special order basis).

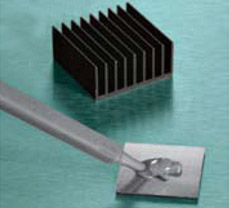

R10404 closed-cell conformable silicone rubber sponge is designed for use where both conformability and heat transfer are necessary, such as between printed circuit boards and heat sinks, decal transfer or applying heat activated adhesives. -

F-12 Silicone Foam Tape

Low-density, flame-retardant COHRlastic silicone foam yard goods provide outstanding performance for industries ranging from aviation and mass transit to automotive, electronics, construction and furniture.

In addition to a UL94V-0 listing in thicknesses down to 1/16", it withstands a 2100 °F flame for more than 10 minutes without burning through in thicknesses down to 3/8".

The material, which has a nominal density of 12 pounds per cubic foot, generates very little white smoke.

Non-corrosive for use with metals and in hostile environments, it has low compression set. Among its applications are fireblocks, thermal barriers, noise and vibration dampeners, insulation and high-performance gaskets or seals.

For the aviation, automotive and mass transit industries, it offers a high degree of design flexibility. Lightweight and easy to process, it can be laminated to seat cover fabrics and carpeting as a backing for added flame resistance in passenger compartment furnishings.

The material has similar uses in institutional and residential furnishings, marine and lighting applications. It offers properties valuable in flame retardant backings for floor,wall and furniture coverings; fire-wall and thermal barriers or insulation, padding and gasketing for commercial and private marine vehicles; or gasketing and sealing in high- intensity light fixtures and electronic components in medical, computer and business equipment.

Colored gray, it is supplied in 18" and 36" wide roll stock. Thicknesses are shown in the table below. It is available plain or, on special order, laminated to any of a wide range of substrates.

Because of the unique nature of COHRlastic foam, SGPPL CHR has undertaken a rigorous testing program which is performed at outside independent laboratories.

The tests document the flame resistant properties and low levels of toxicity and smoke generation as well as mechanical and electrical properties. Details are on file at SGPPL CHR.

Tests, claims, representations and descriptions regarding flamability are based on standard laboratory tests and, as such, may not be reliable for determining, evaluating, predicting or describing the flammability or burning characteristics under actual fire conditions, whether used alone or in combination with other products. Accordingly, each potential user should make an individual determination whether the flammability or burning characteristics of the product are suitable for the purpose intended by the user.

CHR provides certification to the specifications listed when requested with order. All properties are typical values and should not be used for writing specifications. Please consult plant concerning updated specifications. Government and military specifications are being revised at the time of this catalog printing.

Robert McKeown offers a variety of adhesive and sealant products for a wide range of commercial and industrial applications. Our silicone epoxy adhesives and sealants, in particular, are ideal for applications such as:

FEATURES AND USES OF ELECTRONICS SEALANTS AND ADHESIVES

Providing ultimate reliability and longevity, our electronics adhesives and sealants can be used to form bonds to many different surfaces and substrates, including:

- Ceramics

- Metals

- Glass

- Filled plastics

These specialized solutions eliminate the need for mechanical fastening and clamping while allowing for optimal ease of processing. Reliable and efficient in temperatures ranging from -45 °C to 200 °C, our electronics adhesives and sealants provide excellent dielectric insulation.

Most silicone formulations are solventless, eliminating the need for special storage, ventilation, or handling. And because many of our electronics adhesives and solvents are reworkable, they offer great flexibility and allow for easier module repair.

Electronics adhesives and sealants are frequently used in: automotive, communications, industrial, and energy industries, as well as consumer devices.

Extremely versatile, these adhesives can be used for:

- Sealing lids and housing grooves

- Cushioning or stabilizing fragile components

- Affixing components such as capacitors and coils to circuit boards

- Adhering module lids and baseplates

- Gasketing

SILICONE ADHESIVES

One of the most popular types of electronics adhesives, silicone adhesives provide excellent flexibility and high heat resistance, making them ideal for electrical, automotive, aerospace, and construction industries. There are several varieties of silicone adhesives available, including:

- Two-component systems that require a curing agent

- One-component systems that cure through air moisture

- UV or EB radiation curing adhesives

- Pressure-sensitive versions that adhere to surfaces with little pressure

RTV sealants (room-temperature vulcanizing) begin to cure as soon as they’re exposed to moisture in the air, so they must be used quickly. Pressure-sensitive sealants offer a permanent tackiness. UV- or radiation-cured sealants, on the other hand, require UV light to cure, while thermoset silicone sealants require heat to cure. Although not as strong as other sealants or adhesives, electrical silicone sealants remain flexible even when fully dried or cured. Various types of silicone sealants serve as ideal solutions for high-heat applications like engine gaskets.

In electronics fabrication, silicone adhesive sealants are often used for fixing parts on circuit boards, LCD module assembly, general sealing, and component protection. Specific formulations differ depending on intended use and can be customized to allow for enhanced thermal conductivity, superior protection of metal electrodes, and faster cure times. These sealants are available in chemical-, heat-, mildew-, and oil-resistant formulations to meet a wide range of application needs.

Industrial silicone epoxy is used for:

- General-purpose fixture sealing of tubs

- Windows, ductwork

- Gaskets

- General-purpose bonding

- Sealing

THERMAL SEALANTS

High temperatures often present problems for conventional adhesive materials and can affect printed circuit boards and assemblies. At Robert McKeown, we offer the highest-level special adhesive grades of thermal sealants, which allow for enhanced thermal conductivity. Both low-viscosity liquids and non-slump formations are available in two-cure chemistries.

We also offer one-part moisture-cure grades, which use room-temperature processing to cut back on equipment needs. After cure, the materials form strong but flexible bonds, which protect from mechanical stress and vibration. Both one- and two-part heat-cure solutions accelerate processing and support high throughput production.

Heat resistant silicone adhesives are extremely versatile materials and dispense easily at room temperature, but can also cure quickly at any thickness level at temperatures as low as 90°C. Efficacy and functionality are improved when higher temperatures accelerate cure times.

CHEMICAL RESISTANT ADHESIVES

Chemical resistant silicone adhesives are commonly used in:

- Chemical processing plants

- Chemical piping and tanks

- Medical devices

These adhesives can reliably protect against a wide range of chemicals and harsh materials, including acid, alcohol, and fuel. Depending on specific application requirements, they can also provide resistance against solvents, bases, sterilization, and water.

EPOXY BASED ADHESIVES

Epoxy based adhesives are created by mixing a resin and a hardener. Curing is initiated when the resin is mixed with a certain catalyst. The covalent bonds resulting from this combination determine the rigidity and strength of the epoxy sealant.

Epoxy adhesives can reliably adhere to a variety of materials and are ideal for applications demanding chemical resistance, high strength, and low stress. Thermally conductive, microelectronic-grade, general-purpose, high-temperature and chemical resistant epoxy adhesives are available as both one- and two-part solutions. Epoxy adhesive and sealants allow for room temperature, thermal, or UV-curing capabilities.