-

General Purpose Tapes

general-purpose-tapes

-

Paper Masking Tape

Masking Tapes designed for temporary holding applications during construction of electrical components. Also ideally suited for die-cutting.

-

Rubber Products

Rubber Products

(11)To support electrical equipment that is indispensable to daily life and industry. We provide a full array of insulating tapes and covers for high-voltage lines, including self-fusing tapes and adhesive tapes. Materials ranging from butyl and synthetic rubber to polyethylene and silicone rubber are adapted to suit many specific needs.

-

Silicone Solid Rubber Tape

COHRlastic solid silicone rubber in square sheet and continuous length form has a smooth, blemish-free surface. It is available in degrees of hardness from relatively soft 30 durometer to the relatively hard 70 durometer on the Shore A scale. It is manufactured in different formulations to provide a choice of physical properties and cost considerations.

Series 300-700 COHRlastic generalpurpose molded sheet is available in thicknesses up to 1/2" and it withstands temperatures from –100 °F to +500 °F.

Series 9030 - 9070 COHRlastic is also general-purpose, but is produced in 36" wide continuous lengths for the most efficient utilization of material, minimizing waste. Standard thicknesses are 1/32", 1/16" and 1/8".Withstands temperatures from –100 °F to +500 °F. Please consult plant for availability of additional thicknesses and colors.

Series 9200 high-performance COHRlastic provides excellent tensile strength and superior tear resistance. It is tougher and more resilient than generalpurpose silicone. Standard thicknesses are 1/32", 1/16" and 1/8", and it withstands temperatures ranging from –100°F to +400 °F. A minimum thickness of .015" is available on a minimum quantity basis. Red color is standard for general-purpose goods. Black or gray can be provided on a minimum quantity basis.The 9200 series is standard in gray, but clear or red can be supplied on a minimum quantity basis. Contact plant for minimums. -

Reinforced Solid Rubber Tape

CF silicone solid rubber reinforced with fiberglass is a dimensionally-stable, durable material for press pads, belting and gasketing. It is available in six constructions.

CF3320, available in three thicknesses, was developed to meet AMS 3320. Consequently, 3320 has lubricating oil resistance and excellent compression set resistance.

CF4032 and CF4050 are thin, flexible and abrasion-resistant for generalpurpose use.

CF4420 is specially formulated for thermal stability and long life under extreme heat and pressure for extended dwell times. It resists reversion (i.e. softening and outgassing) longer than general purpose silicone. Throughout its useful life, 4420 has thermal stability for consistent thermal conductivity.

CF4444 has a specially formulated rubber compound to give better reversion resistance. The reinforcement is a special crush-resistant fiberglass, making the product excellent for press pads in high-temperature and pressure lamination applications.

CF4451 is a fiberglass fabric coated with static dissipating silicone rubber having a surface resistivity of 1 x 105Ohms – cm.Virtually eliminates static electric discharges which cause operator discomfort and can potentially damage electrical laminates.

CF4480 utilizes our most reversionresistant silicone rubber compound. The product is designed for use in applications involving the tough combination of prolonged high-pressure confinement at temperatures in the range of 375 °F to 650 °F. -

Silicone Sponge Rubber Tape

Flexible, compressible COHRlastic silicone closed cell sponge is designed for high-performance gasketing, thermal shielding, vibration mounts and press pads. It is available in six constructions.

R10470, a general-purpose silicone sponge, can be used in most applications.

R10480 has extremely low compression set and maintains its resiliency even under extended compression.

R10460 is flame retardant.When held in a vertical position and exposed to a 2,000 °F flame for 12 seconds, there is no residential flame and less than a 10 second afterglow. Like R10480, it is especially resistant to compression set.

R10450 silicone sponge with fiberglass reinforcement is a unique construction. It has the compressibility of sponge, plus dimensional stability in the X-Y direction. The absence of stretch contributes to the consistent size and shape of die cut parts and eliminates outward extrusion under pressure.

R10490 fluorosilicone sponge rubber can be used as a gasket where it is necessary to contain fluids that would degrade normal silicone sponge and solid materials (special order basis).

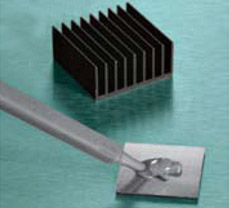

R10404 closed-cell conformable silicone rubber sponge is designed for use where both conformability and heat transfer are necessary, such as between printed circuit boards and heat sinks, decal transfer or applying heat activated adhesives. -

Strip-N-Stick Silicone Tape

Strip-N-Stick® tape provides all the benefits of silcone rubber in an easy-to-apply, pressure-sensitive adhesive tape form. Compressible and flexible, it can conform to irregular surfaces, wrap over cylinders or be formed to produce right angles. Applications include gasketing, vibration damping, and thermal insulation.The tape reduces the need for expensive diecut- parts – you don‘t pay for the center. It also eliminates the high cost of bonding and will be slit to order from 1/2" and up.

100S is a silicone sponge with high temperature silicone adhesive.

200A is a silicone sponge with aggressive acrylic adhesive.

300AR is reinforced silicone sponge with aggressive acrylic adhesive. Its unique construction provides compressibility of sponge and dimensional stability of fiberglass reinforcement. Stretch is eliminated, which contributes to the consistent size and shape of cut parts and inhibits outward extrusion under high pressure. It further permits close tolerance slitting.

440S is a 1/32" thick Shore A 30 durometer silicone solid with high-temperature silicone adhesive.

440A combines 30 durometer solid rubber with a high-adhesion acrylic adhesive for an excellent 1/32" thick gasket material. It provides high elongation and good comformability.

512AF uses SGPPL CHR’s silicone foam along with film-supported acrylic pressure-sensitive adhesive.

Adhesive temperature range for Silicone PSA is –100 °F to +500 °F and for Acrylic PSA, –20 °F to +300 °F. -

F-12 Silicone Foam Tape

Low-density, flame-retardant COHRlastic silicone foam yard goods provide outstanding performance for industries ranging from aviation and mass transit to automotive, electronics, construction and furniture.

In addition to a UL94V-0 listing in thicknesses down to 1/16", it withstands a 2100 °F flame for more than 10 minutes without burning through in thicknesses down to 3/8".

The material, which has a nominal density of 12 pounds per cubic foot, generates very little white smoke.

Non-corrosive for use with metals and in hostile environments, it has low compression set. Among its applications are fireblocks, thermal barriers, noise and vibration dampeners, insulation and high-performance gaskets or seals.

For the aviation, automotive and mass transit industries, it offers a high degree of design flexibility. Lightweight and easy to process, it can be laminated to seat cover fabrics and carpeting as a backing for added flame resistance in passenger compartment furnishings.

The material has similar uses in institutional and residential furnishings, marine and lighting applications. It offers properties valuable in flame retardant backings for floor,wall and furniture coverings; fire-wall and thermal barriers or insulation, padding and gasketing for commercial and private marine vehicles; or gasketing and sealing in high- intensity light fixtures and electronic components in medical, computer and business equipment.

Colored gray, it is supplied in 18" and 36" wide roll stock. Thicknesses are shown in the table below. It is available plain or, on special order, laminated to any of a wide range of substrates.

Because of the unique nature of COHRlastic foam, SGPPL CHR has undertaken a rigorous testing program which is performed at outside independent laboratories.

The tests document the flame resistant properties and low levels of toxicity and smoke generation as well as mechanical and electrical properties. Details are on file at SGPPL CHR.

Tests, claims, representations and descriptions regarding flamability are based on standard laboratory tests and, as such, may not be reliable for determining, evaluating, predicting or describing the flammability or burning characteristics under actual fire conditions, whether used alone or in combination with other products. Accordingly, each potential user should make an individual determination whether the flammability or burning characteristics of the product are suitable for the purpose intended by the user.

CHR provides certification to the specifications listed when requested with order. All properties are typical values and should not be used for writing specifications. Please consult plant concerning updated specifications. Government and military specifications are being revised at the time of this catalog printing. -

Film-UHMW Backing Substrates

UHMW polyolefin film tape provides anti-sticking and abrasion resistance properties for application temperatures ranging from -100°F to 225°F (-73°C to +107°C). Applications include bearings, chute and guide rail coverings.

Robert McKeown offers a variety of adhesive and sealant products for a wide range of commercial and industrial applications. Our silicone epoxy adhesives and sealants, in particular, are ideal for applications such as:

FEATURES AND USES OF ELECTRONICS SEALANTS AND ADHESIVES

Providing ultimate reliability and longevity, our electronics adhesives and sealants can be used to form bonds to many different surfaces and substrates, including:

- Ceramics

- Metals

- Glass

- Filled plastics

These specialized solutions eliminate the need for mechanical fastening and clamping while allowing for optimal ease of processing. Reliable and efficient in temperatures ranging from -45 °C to 200 °C, our electronics adhesives and sealants provide excellent dielectric insulation.

Most silicone formulations are solventless, eliminating the need for special storage, ventilation, or handling. And because many of our electronics adhesives and solvents are reworkable, they offer great flexibility and allow for easier module repair.

Electronics adhesives and sealants are frequently used in: automotive, communications, industrial, and energy industries, as well as consumer devices.

Extremely versatile, these adhesives can be used for:

- Sealing lids and housing grooves

- Cushioning or stabilizing fragile components

- Affixing components such as capacitors and coils to circuit boards

- Adhering module lids and baseplates

- Gasketing

SILICONE ADHESIVES

One of the most popular types of electronics adhesives, silicone adhesives provide excellent flexibility and high heat resistance, making them ideal for electrical, automotive, aerospace, and construction industries. There are several varieties of silicone adhesives available, including:

- Two-component systems that require a curing agent

- One-component systems that cure through air moisture

- UV or EB radiation curing adhesives

- Pressure-sensitive versions that adhere to surfaces with little pressure

RTV sealants (room-temperature vulcanizing) begin to cure as soon as they’re exposed to moisture in the air, so they must be used quickly. Pressure-sensitive sealants offer a permanent tackiness. UV- or radiation-cured sealants, on the other hand, require UV light to cure, while thermoset silicone sealants require heat to cure. Although not as strong as other sealants or adhesives, electrical silicone sealants remain flexible even when fully dried or cured. Various types of silicone sealants serve as ideal solutions for high-heat applications like engine gaskets.

In electronics fabrication, silicone adhesive sealants are often used for fixing parts on circuit boards, LCD module assembly, general sealing, and component protection. Specific formulations differ depending on intended use and can be customized to allow for enhanced thermal conductivity, superior protection of metal electrodes, and faster cure times. These sealants are available in chemical-, heat-, mildew-, and oil-resistant formulations to meet a wide range of application needs.

Industrial silicone epoxy is used for:

- General-purpose fixture sealing of tubs

- Windows, ductwork

- Gaskets

- General-purpose bonding

- Sealing

THERMAL SEALANTS

High temperatures often present problems for conventional adhesive materials and can affect printed circuit boards and assemblies. At Robert McKeown, we offer the highest-level special adhesive grades of thermal sealants, which allow for enhanced thermal conductivity. Both low-viscosity liquids and non-slump formations are available in two-cure chemistries.

We also offer one-part moisture-cure grades, which use room-temperature processing to cut back on equipment needs. After cure, the materials form strong but flexible bonds, which protect from mechanical stress and vibration. Both one- and two-part heat-cure solutions accelerate processing and support high throughput production.

Heat resistant silicone adhesives are extremely versatile materials and dispense easily at room temperature, but can also cure quickly at any thickness level at temperatures as low as 90°C. Efficacy and functionality are improved when higher temperatures accelerate cure times.

CHEMICAL RESISTANT ADHESIVES

Chemical resistant silicone adhesives are commonly used in:

- Chemical processing plants

- Chemical piping and tanks

- Medical devices

These adhesives can reliably protect against a wide range of chemicals and harsh materials, including acid, alcohol, and fuel. Depending on specific application requirements, they can also provide resistance against solvents, bases, sterilization, and water.

EPOXY BASED ADHESIVES

Epoxy based adhesives are created by mixing a resin and a hardener. Curing is initiated when the resin is mixed with a certain catalyst. The covalent bonds resulting from this combination determine the rigidity and strength of the epoxy sealant.

Epoxy adhesives can reliably adhere to a variety of materials and are ideal for applications demanding chemical resistance, high strength, and low stress. Thermally conductive, microelectronic-grade, general-purpose, high-temperature and chemical resistant epoxy adhesives are available as both one- and two-part solutions. Epoxy adhesive and sealants allow for room temperature, thermal, or UV-curing capabilities.