| Items |

82-111-74018

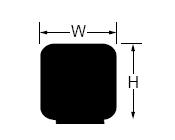

SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips

|

82-111-74017

SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips

|

82-111-74022

SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips

|

82-111-74024

SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips

|

82-111-74028

SOFT-SHIELD® 5000 Low Closure Force EMI Strip Gaskets - Square Strips

|

|

Jacket Type

|

N/A

Nickel-plated nylon rip-stop fabric

|

|

PSA Tape Backing

|

N/A

No PSA tape

|

|

Gasket Service Rating

|

N/A

General duty (urethane foam core)

|

|

Profile Number

|

N/A

74018

|

N/A

74017

|

N/A

74022

|

N/A

74024

|

N/A

74028

|

|

Height

|

N/A

0.118 in3.00 mm

|

N/A

0.200 in5.08 mm

|

N/A

0.236 in6.00 mm

|

N/A

0.375 in9.53 mm

|

N/A

0.500 in12.70 mm

|

|

Width

|

N/A

0.118 in3.00 mm

|

N/A

0.200 in5.08 mm

|

N/A

0.236 in6.00 mm

|

N/A

0.375 in9.53 mm

|

N/A

0.500 in12.70 mm

|

|

Conductive Pressure-Sensitive Adhesive

|

N/A

Non-conductive adhesive

|

|

Operating Temperature Range

|

N/A

–40 to 70 ºC

|

|

Test Method Compression Set

|

N/A

ASTM D3574 (modified)

|

|

Compression Set

|

N/A

< 15 %

|

|

Test Method Electrical Conductivity

|

N/A

CEPS-0002

|

|

Electrical Conductivity Max.

|

N/A

0.1 O/sq

|

|

Test Method Adhesive Peel Strength

|

N/A

ASTM D1000 (90° Bend)

|

|

Adhesive Peel Strength Min.

|

N/A

4 lb/in0.7 N/mm

|

|

Product Forms

|

N/A

SQ, REC., D, C, P, L and Custom

|

|

Typical Applications

|

N/A

Doors, Panels, Seams, Faceplates, Ground Pads

|

|

Method of Manufacture

|

N/A

Dispensed foam

|

|

Jacket Material

|

N/A

Ni/Ag Plated rip-stop Nylon

|

|

Foam

|

N/A

High Performance Urethane Foam

|

|

Attachment Method (PSA)

|

N/A

Non conductive, high temp, high tack, closed cell, acrylic PSA

|

|

Baseline EMI Shielding

|

N/A

90 dB

|

|

Shielding Effectiveness After Cycling

|

N/A

Better

|

|

Softness

|

N/A

Better

|

|

Compression Set ASTM D395 - Method B

|

N/A

70 ºC - 10 %

|

|

RoHS Compliant

|

N/A

Yes

|

|

Configurations

|

N/A

Gaskets are supplied in standard 8-foot lengths or cut-to-length strips. Depending on the profile, gasketing can also be supplied on spools. For rapid peel-and-stick grounding applications, the material is supplied as kiss-cut parts on polyester film release backers, or as individual pieces. Chomerics also fabricates single-piece, spliced picture frame gaskets from continuous lengths. With their fully jacketed surfaces, these gaskets are ideally suited for low closure force applications that require 360° EMI shielding, or the ease of installing a onepiece gasket.

Chomerics’ Applications Engineering department welcomes the opportunity to provide assistance with design and prototype fabrication of SOFT-SHIELD 5000 Series EMI Gaskets in custom profiles.

|

|

Typical Application-Ready Solutions

|

N/A

Mobile phone grounding

Conditions and Requirements

minimize thru-resistance for optimum groundingmaximum 0.25 x 0.25 inch footprintaccommodate 0.040 inch variation in gapsnap-in plastic cover with 2 lb max. load at 50% gasket deflectionhigh volume application

SOFT-SHIELD Gasket Solution

highly conductive jacket offers low resistancestandard 6 x 6 mm profile, no customization requiredmeets low closure force requirementskiss-cut parts on release paper allow quick peel-and-stick installation

Interface between aluminum casting and plastic antenna housing

Conditions and Requirements

overcome 45 dB leakage problemreplace multiple strips with single-piece design for ease of installation0.030 inch flatness tolerance on component mating surfaceslow cost a priority

SOFT-SHIELD Gasket Solution

effectively

|

|

Typical Tolerances

|

N/A

Typical cross section tolerances:

±0.010 in. (0.25 mm) for all dimensions up to 0.04 in. (1.02 mm)

±0.020 in. (0.51 mm) for all dimensions above 0.04 in. (1.02 mm)

Detailed part drawings are available on request.

Typical length tolerances:

0.10 to 6.0 in. (0.25 to 15.2 cm) ± 0.030 in. (0.76 mm)

6.1 to 18.0 in. (15.5 to 45.7 cm) ± 0.060 in. (1.52 mm)

18.1 to 42.0 in. (46.0 to 106.7 cm) ± 0.075 in. (1.91 mm)

42.1 to 96.0 in. (107.0 to 243.8 cm) ± 0.090 in. (2.29 mm)

Typical kiss-cut tolerances:

0.04 to 0.12 in. (1.02 to 3.05 mm) ± 0.015 in. (0.38 mm)

0.121 to 0.40 in. (3.07 to 10.16 mm) ± 0.035 in. (0.89 mm)

|