| Items |

SE4422 Adhesive

Dow Electronics Thermally Conductive Adhesives/Sealants

|

SE9184 CV Adhesive

Dow Electronics Thermally Conductive Adhesives/Sealants

|

SE4450 Adhesive

Dow Electronics Thermally Conductive Adhesives/Sealants

|

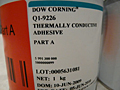

1-4173 Adhesive

Dow Electronics Thermally Conductive Adhesives/Sealants

|

1-4174 Adhesive

Dow Electronics Thermally Conductive Adhesives/Sealants

|

|

Type

|

N/A

Thermally Conductive Adhesives

|

|

Product Form

|

N/A

One-Part

|

|

Color

|

N/A

Gray

|

N/A

White

|

N/A

Gray

|

N/A

Gray

|

N/A

Gray

|

|

Viscosity

|

N/A

200000 mPa/s

|

N/A

Non-flow

|

N/A

61000 mPa/s

|

N/A

58000 mPa/s

|

N/A

58000 mPa/s

|

|

Durometer

|

N/A

69 A

|

N/A

72 A

|

N/A

95 A

|

N/A

92 A

|

N/A

92 A

|

|

Penetration (1/10 of mm)

|

N/A

|

|

Tensile Strength

|

N/A

754 psi5.2 MPa53 kgf/cm²

|

N/A

421 psi2.9 MPa29.6 kgf/cm²

|

N/A

1044 psi7.2 MPa73.4 kgf/cm²

|

N/A

900 psi6.2 MPa63.3 kgf/cm²

|

N/A

900 psi6.2 MPa63.3 kgf/cm²

|

|

Elongation

|

N/A

120 %

|

N/A

70 %

|

N/A

40 %

|

N/A

20 %

|

N/A

|

|

Specific Gravity

|

N/A

2.17

|

N/A

|

N/A

2.74

|

N/A

2.7

|

N/A

2.71

|

|

Compression Modulus at 10 %

|

N/A

|

|

Linear CTE

|

N/A

203 µ/mC

|

N/A

|

N/A

|

N/A

126 µ/mC

|

N/A

|

|

Working Time at Room Temperature1

|

N/A

< 10 min

|

N/A

|

N/A

|

N/A

|

N/A

|

|

Room Temperature Cure Time2

|

N/A

144 h

|

N/A

48 h

|

N/A

|

N/A

|

N/A

|

|

Heat Cure Time at 100 ºC (212 ºF)3

|

N/A

|

N/A

|

N/A

|

N/A

90 min

|

N/A

90 min

|

|

Heat Cure Time at 120 ºC

|

N/A

|

|

Heat Cure Time at 125 ºC (257 ºF)4

|

N/A

|

N/A

|

N/A

|

N/A

30 min

|

N/A

30 min

|

|

Heat Cure Time at 150 ºC (302 ºF)5

|

N/A

|

N/A

|

N/A

30 min

|

N/A

20 min

|

N/A

20 min

|

|

Unprimed Adhesion Lap Shear

|

N/A

230 psi160 N/cm²16 kgf/cm²

|

N/A

300 psi205 N/cm²21 kgf/cm²

|

N/A

530 psi365 N/cm²37 kgf/cm²

|

N/A

640 psi440 N/cm²45 kgf/cm²

|

N/A

590 psi405 N/cm²41 kgf/cm²

|

|

Thermal Conductivity6

|

N/A

0.9 W/m·K

|

N/A

0.84 W/m·K

|

N/A

1.97 W/m·K

|

N/A

1.9 W/m·K

|

N/A

1.9 W/m·K

|

|

Shelf Life from Date of Manufacture

|

N/A

9 months

|

N/A

7 months

|

N/A

6 months

|

N/A

6 months at 5 ºC

|

N/A

6 months at 5 ºC

|

|

Dielectric Strength

|

N/A

365 V/mil14.3 kV/mm

|

N/A

508 V/mil20 kV/mm

|

N/A

610 V/mil24 kV/mm

|

N/A

425 V/mil16.7 kV/mm

|

N/A

425 V/mil16.7 kV/mm

|

|

Dielectric Constant at 100 Hz

|

N/A

4.44

|

N/A

|

N/A

|

N/A

4.98

|

N/A

|

|

Dielectric Constant at 1 kHz

|

N/A

|

|

Dielectric Constant at 100 kHz

|

N/A

4.38

|

N/A

|

N/A

|

N/A

4.86

|

N/A

4.63

|

|

Dielectric Constant at 1 MHz

|

N/A

4.9

|

N/A

3.9

|

N/A

4.7

|

N/A

|

N/A

|

|

Dissipation Factor at 100 Hz

|

N/A

0.00498

|

N/A

|

N/A

|

N/A

0.008

|

N/A

|

|

Dissipation Factor at 1 kHz

|

N/A

|

|

Dissipation Factor at 100 kHz

|

N/A

0.00498

|

N/A

|

N/A

|

N/A

< 0.003

|

N/A

0.0021

|

|

Dissipation Factor at 1 MHz

|

N/A

0.006

|

N/A

0.002

|

N/A

0.002

|

N/A

|

N/A

|

|

Volume Resistivity

|

N/A

5.00E+15 O/cm

|

N/A

1.00E+15 O/cm

|

N/A

2.00E+15 O/cm

|

N/A

2.20E+14 O/cm

|

N/A

1.90E+14 O/cm

|