| Items |

HCS10

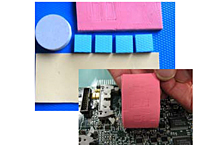

THERM-A-GAP™ - Thermally Conductive Gap Filler Pads

|

569

THERM-A-GAP™ - Thermally Conductive Gap Filler Pads

|

570

THERM-A-GAP™ - Thermally Conductive Gap Filler Pads

|

579-Gap Filler

THERM-A-GAP™ - Thermally Conductive Gap Filler Pads

|

580

THERM-A-GAP™ - Thermally Conductive Gap Filler Pads

|

|

Test Method Color

|

N/A

Visual

|

|

Color

|

N/A

Orange

|

N/A

Gray

|

N/A

Blue

|

N/A

Pink

|

N/A

Yellow

|

|

Carrier

|

N/A

Aluminum foil - with PSA Woven glass - no PSA

|

|

Test Method Thicknesses

|

N/A

ASTM D374

|

|

Standard Thickness1

|

N/A

0.25–5.0 mm0.010–0.200 in

|

N/A

0.25–5.0 mm0.010–0.200 in

|

N/A

0.5–5.0 mm0.020–0.200 in

|

N/A

0.25–5.0 mm0.010–0.200 in

|

N/A

0.5–5.0 mm0.020–0.200 in

|

|

Test Method Specific Gravity

|

N/A

ASTM D792

|

|

Specific Gravity

|

N/A

2.0

|

N/A

2.2

|

N/A

2.2

|

N/A

2.9

|

N/A

2.9

|

|

Test Method Hardness

|

N/A

ASTM D2240

|

|

Hardness, Shore 00

|

N/A

4

|

N/A

10

|

N/A

25

|

N/A

30

|

N/A

45

|

|

Test Method Extractable Silicone

|

N/A

Chomerics

|

|

Extractable Silicone

|

N/A

|

N/A

10 %

|

N/A

10 %

|

N/A

6 %

|

N/A

6 %

|

|

Test Method Percent Deflection at Various Pressures

|

N/A

ASTM C165 MOD (0.125 in “G” Type, 0.50 in dia. probe, 0.025 in/min rate)

|

|

Percent Deflection at Various Pressures (0.125 in) at 34 kPa (5 psi) Deflected

|

N/A

26 %

|

N/A

20 %

|

N/A

10 %

|

N/A

22 %

|

N/A

7 %

|

|

Percent Deflection at Various Pressures (0.125 in) at 69 kPa (10 psi) Deflected

|

N/A

36 %

|

N/A

30 %

|

N/A

15 %

|

N/A

33 %

|

N/A

10 %

|

|

Percent Deflection at Various Pressures (0.125 in) at 172 kPa (25 psi) Deflected

|

N/A

59 %

|

N/A

50 %

|

N/A

25 %

|

N/A

55 %

|

N/A

20 %

|

|

Percent Deflection at Various Pressures (0.125 in) at 345 kPa (50 psi) Deflected

|

N/A

73 %

|

N/A

35 %

|

N/A

35 %

|

N/A

68 %

|

N/A

30 %

|

|

Operating Temperature Range

|

N/A

–55 to 200 ºC–67 to 392 ºF

|

|

Test Method Thermal Impedance

|

N/A

ASTM D5470

|

|

Thermal Impedance at 10 psi, at 1mm Thickness, G Version

|

N/A

9.7 ºC-cm²/W1.5 ºC-in²/W

|

N/A

9.1 ºC-cm²/W1.4 ºC-in²/W

|

N/A

9.1 ºC-cm²/W1.4 ºC-in²/W

|

N/A

4.5 ºC-cm²/W0.7 ºC-in²/W

|

N/A

4.5 ºC-cm²/W0.7 ºC-in²/W

|

|

Test Method Thermal Conductivity

|

N/A

ASTM D5470

|

|

Thermal Conductivity

|

N/A

1 W/m·K

|

N/A

1.5 W/m·K

|

N/A

1.5 W/m·K

|

N/A

3 W/m·K

|

N/A

3 W/m·K

|

|

Test Method Heat Capacity

|

N/A

ASTM E1269

|

|

Heat Capacity

|

N/A

1 J/g-K

|

|

Test Method Coefficient of Thermal Expansion

|

N/A

ASTM E831

|

|

Coefficient of Thermal Expansion

|

N/A

|

N/A

250 ppm/K

|

N/A

250 ppm/K

|

N/A

150 ppm/K

|

N/A

150 ppm/K

|

|

Test Method Dielectric Strength

|

N/A

ASTM D149

|

|

Dielectric Strength

|

N/A

8 KVac/mm200 Vac/mil

|

|

Test Method Volume Resistivity

|

N/A

ASTM D257

|

|

Volume Resistivity

|

N/A

1014 O/cm

|

|

Test Method Dielectric Constant

|

N/A

ASTM D150

|

|

Dielectric Constant at 1000 kHz

|

N/A

5.3

|

N/A

6.5

|

N/A

6.5

|

N/A

8.0

|

N/A

8.0

|

|

Test Method Dissipation Factor

|

N/A

Chomerics Test

|

|

Dissipation Factor at 1000 kHz

|

N/A

0.013

|

N/A

0.013

|

N/A

0.013

|

N/A

0.010

|

N/A

0.010

|

|

Conformability Rating

|

N/A

|

N/A

1

|

N/A

|

N/A

1

|

N/A

|

|

Test Method Flammability Rating

|

N/A

UL 94

|

|

Flammability Rating

|

N/A

Not tested

|

N/A

V-0

|

N/A

V-0

|

N/A

V-0

|

N/A

V-0

|

|

Test Method RoHS Compliant

|

N/A

Chomeric Certification

|

|

RoHS Compliant

|

N/A

Yes

|

|

Test Method Outgassing

|

N/A

ASTM E595

|

|

Outgassing TML

|

N/A

0.44 %

|

N/A

0.42 %

|

N/A

0.35 %

|

N/A

0.19 %

|

N/A

0.18 %

|

|

Outgassing CVCM

|

N/A

0.13 %

|

N/A

0.08 %

|

N/A

0.09 %

|

N/A

0.06 %

|

N/A

0.05 %

|

|

Test Method Shelf Life

|

N/A

Chomerics

|

|

Shelf Life, Months from Date of Shipment G

|

N/A

24

|

|

Shelf Life, Months from Date of Shipment A

|

N/A

18

|